How to Meet Decarbonization Targets with Simulation

Table of contents

What is Decarbonization?

Decarbonization is the process of lowering carbon dioxide emissions by using low-carbon energy sources and releasing less greenhouse gases into the environment. This process aims to achieve a carbon-free global economy by reducing emissions throughout value chains in a planned and technologically enabled manner. Alternative fuels, electrification, renewable energy, carbon-offset initiatives, product lifecycle assessment methods, and sustainable working practices are all examples of decarbonization approaches.

How Does Decarbonization Affect Your Business?

Consumers and regulatory organizations are calling for manufacturers to meet sustainability targets under a demanding schedule. However, doing so should be viewed as an opportunity rather than a cost. Reduced whole-chain carbon emissions enable your business to gain from making a positive difference in a variety of ways, from accelerating the development of new business models to making more sustainable products.

The Challenges of Decarbonization

Decarbonizing your business cannot be solved with a single stroke. It is a broad, multifaceted challenge that involves changing multiple processes and collaborating with a wide range of stakeholders. It therefore requires solutions that can provide a holistic and realistic view of company-wide operations, allowing businesses to understand the nature of the challenges, and co-ordinate, test, and implement effective responses.

5 Ways Simulation-Driven Design Helps to Make Sustainable Products

Simulation-Driven Design, or Modeling & Simulation (MODSIM) is a data-driven, collaborative, and concurrent approach to product development. Taking this approach enables organizations to improve sustainability throughout product development. Here are our top five opportunities for reducing carbon emissions using simulation tools:

- Material Engineering

- Reducing Waste

- Increasing Durability

- Efficient Energy Use

- Design Optimization

Material Engineering

Material engineering focuses on creating new materials with potentially unique physical features to solve a variety of design problems; replacing existing materials to lessen the environmental impact; and lightweighting materials to withstand a predicted load. In regard to new material discovery, Biomaterials is a particularly promising area for sustainability efforts with the aim of lowering a product’s environmental impact.

Non-linear FEA (Finite Element Analysis) can be used to help guide engineers toward the best material attributes and applications choices. Nonlinear FEA systems (of which Abaqus is a well-known leader) have an edge in this industry since they can accurately simulate severe usage cases like high heat and stress.

Reducing Waste

Most businesses now realize the financial advantages of minimizing waste in their manufacturing process and developing more efficient designs. The simulation of lean manufacturing processes can reveal options for material reuse, productivity optimization, work ergonomics and reduction of transportation paths. Simulation can also improve manufacturing efficiency by iterating processes to reduce failure rates and increase yield percentages. A similar method can also be used to reduce waste from prototype failures by creating more design iterations in a virtual environment.

Increasing Durability

FEA is typically an analytical approach to solving a system of partial differential equations which allows for mechanical stress and structural analysis. Employing structural analysis early in the design phase of product development enables engineers to optimize for durability, creating products with longer lifecycles and reducing the cost of prototyping.

Efficient Energy Use

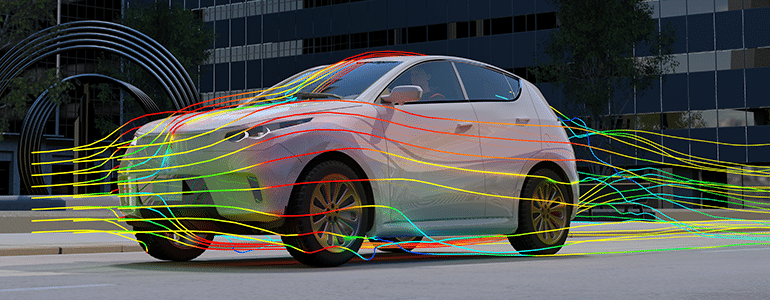

CFD (Computational Fluid Dynamics) is used for simulating fluid flow. Fluid movement (for example, air and water) is a major source of energy loss in many systems owing to drag. Simulation helps to reduce these losses, resulting in less energy being used to power the system, as well as reduced emissions from energy production. System simulations can also be used to optimize energy use. For example, carbon-intensive energy resources can be minimized at peaks loads through analysis of heat distribution system simulations.

Design & Process Optimization

In certain situations, such as aircraft electrification, commercial designs are not yet commercially viable. In these areas, reduction of CO2 emission during manufacture and use, can be achieved through design and process optimization. CFD and FEA analysis can help engineers to optimize aerodynamics and identify opportunities for lightweighting, ultimately improving in-use product sustainability.

In Our Experience…

Improving product sustainability benefits businesses by increasing revenues, productivity, and resource conservation. But the shift toward sustainable product creation also creates various challenges. Adapting product development processes to incorporate simulation in the early design phases can improve cross-discipline collaboration.

Testing new ideas in virtual environments, working together, and achieving better outcomes enables companies to break new ground and bring proven innovations to market, faster.